Cryogenics

Cryogenic Nanopositioners & Scanners

Supplier :

- 90x less heat dissipation than common cryogenic positioner.

- Last 7-10 years thanks to user Replaceable actuators.

- Groundbreaking repeatability and motion resolution.

Low Currents – Higher Voltages

Nanopositioner design for ultra-low temperature environments

Ren-Sci motors are engineered to have significantly lower capacitance compared to conventional cryogenic motor solutions. While competitor motors operate at lower voltages (30-70V) and higher currents (tens of amps), Ren-Sci took a different approach. Their motors run at higher voltages (50-600V) and require only hundreds of milliamps

ABOUT

SYSTEM FEATURES

Ultra low heat dissipation!

Compare a typical leading vendor scenario, 60 V, 1 kHz, 5 uF, so the power pumped into that capacitor is CV^2/2 times frequency which is ~ 9W. The analogous situation for our motors is 200 V, 1 kHz, 5 nF, which is 0.1 W, so using 90x less energy to get the same motion (and thus 90x less heat dissipation)

Spectacular specs

Multidirectional Repeatability: 8 to 150nm

Sensor resolution 2 to 20nm

Closed loop mode minimum incremental motion : 10 nm

Market standard = 5 μm, 200nm, 400 nm

Ren-Sci improves 2 orders of magnitude

Repairability for an outstanding service life

As such, Ren-Sci have intentionally designed his motors to have user exchangeable actuators and we supply 2 extra actuators per axis. So, each axis should easily last 7-10 years, even under heavy use. But even if you go through those sooner, just call us and we’ll overnight you another actuator. Your days of waiting 6 weeks for a repair are over!

UHV and non-magnetic by default

All Ren-Sci motors are UHV compatible, bakeable to 120 C, and made with non-magnetic materials

Purpose built for cryo

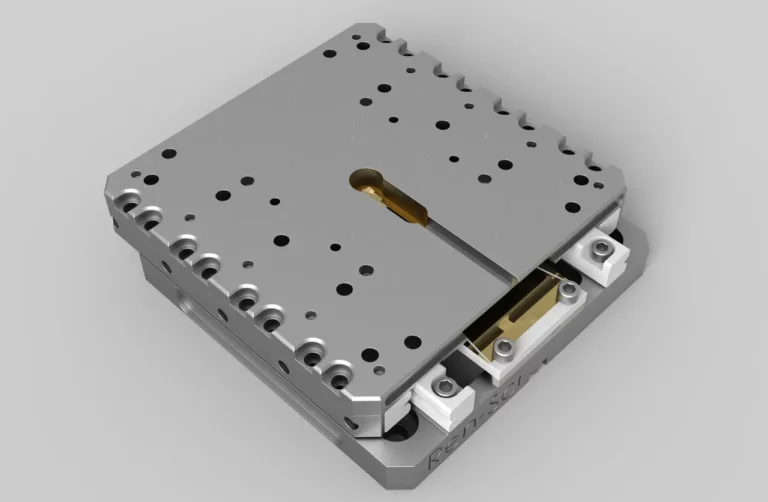

Several suppliers for ambient piezo based motors will simply try to plop it in a cryostat and hope for the best. Our motors were carefully engineered with extreme attention to thermal contraction, capacitance losses in cryo, minimal friction at the bearing interfaces, and low current operation

Excellence in craftsmanship

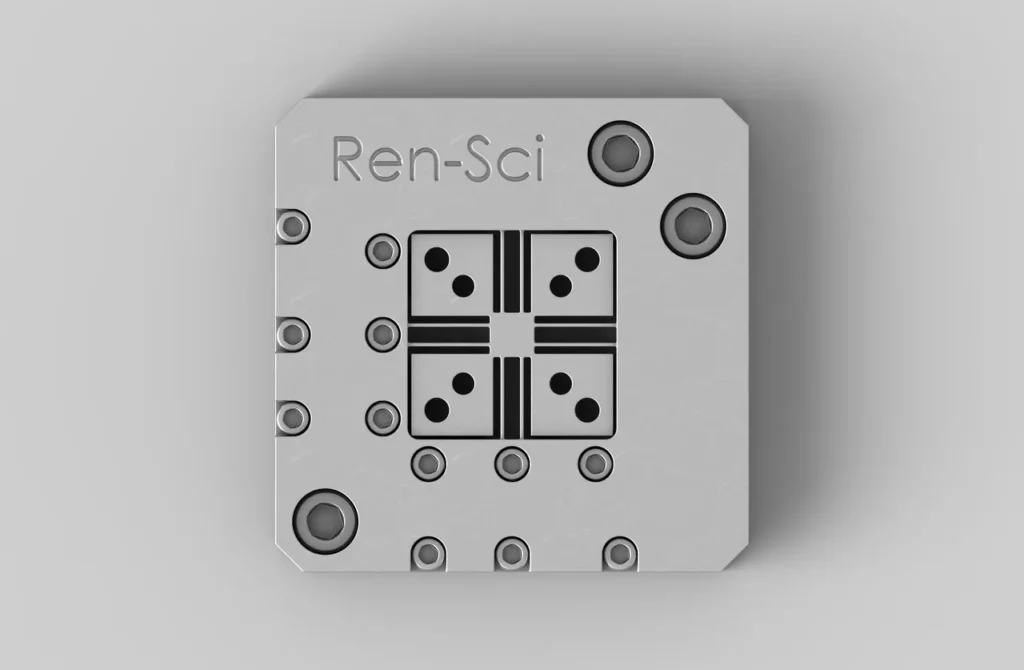

No lubricants are used, solid-state or otherwise. Instead, we use diamond polished surfaces and extremely high precision on our machined parts (sub 2um parallelism on every part), so that there is no need for the use of lubricants

PRODUCT

SPECIFICATIONS

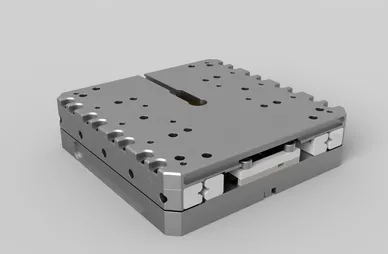

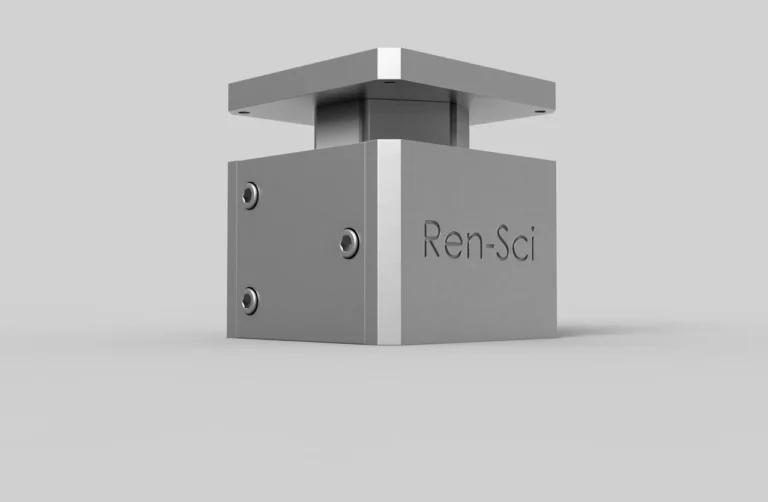

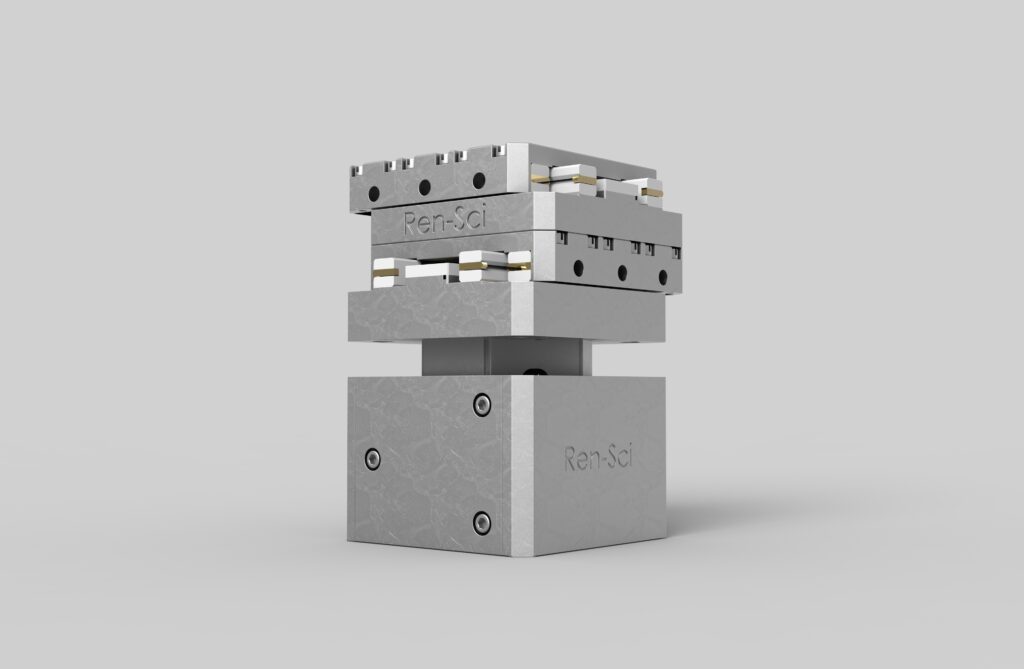

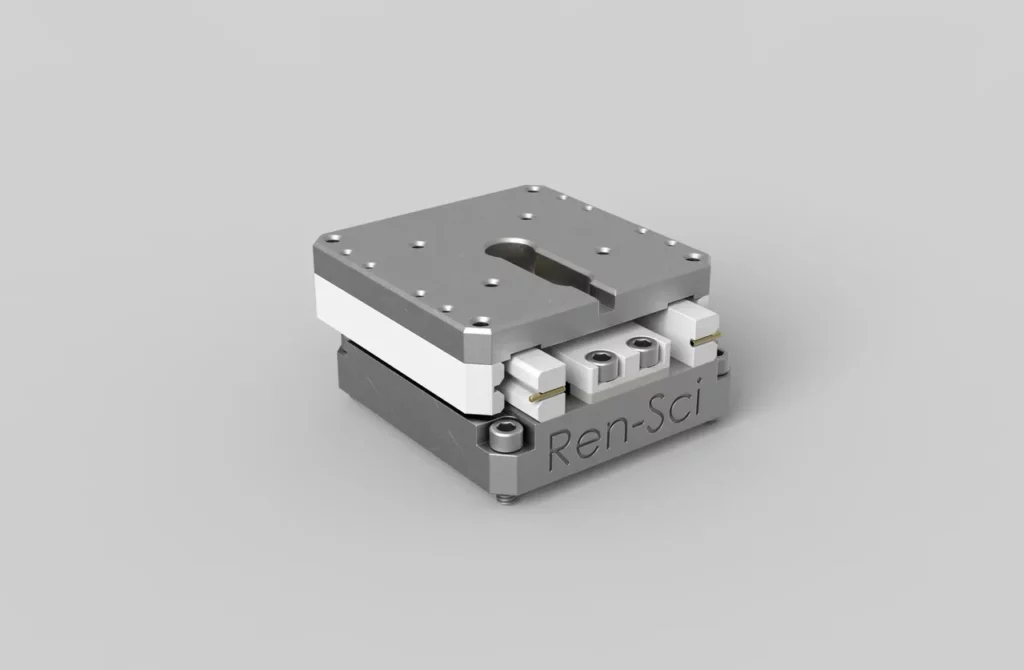

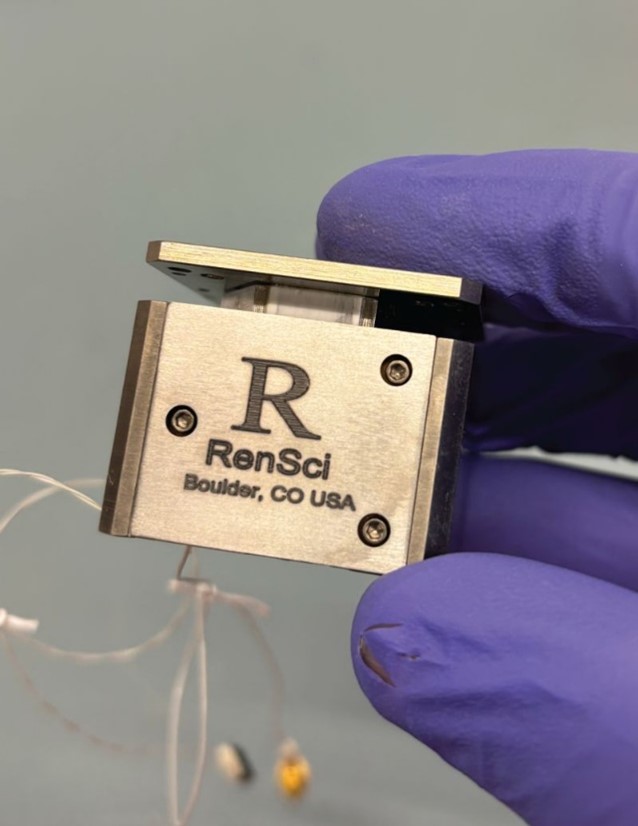

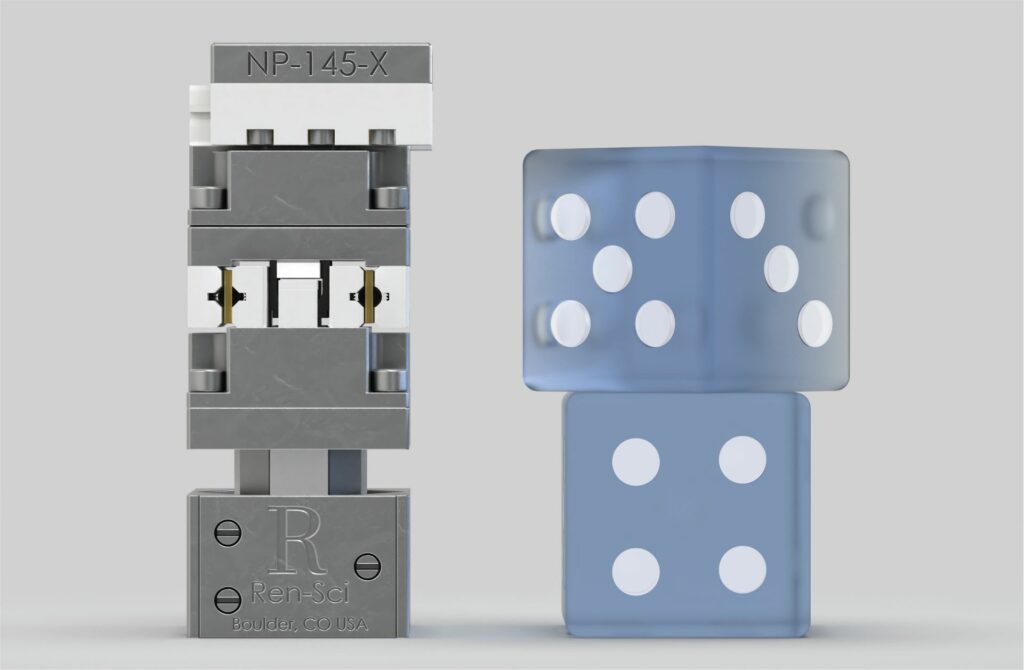

NP- 140-X

- Footprint: 14.5mm x 14.5mm x 8mm

- Range: 3 mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

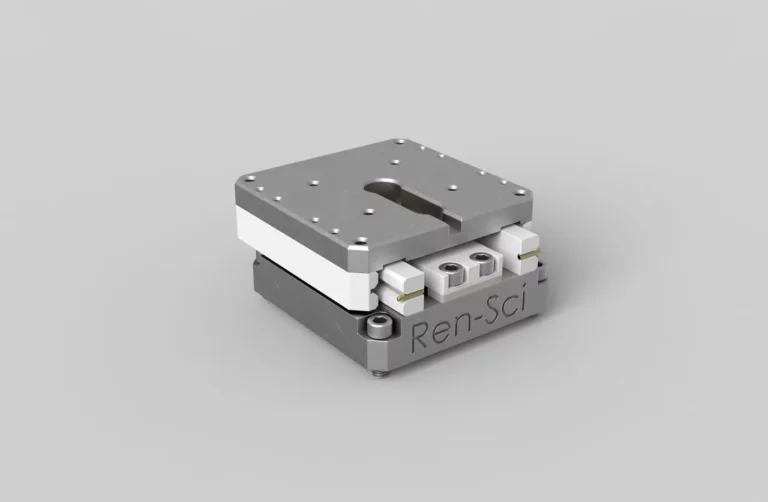

NP-240-X

- Footprint: 24mm x 24mm x 12mm

- Range: 5 mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

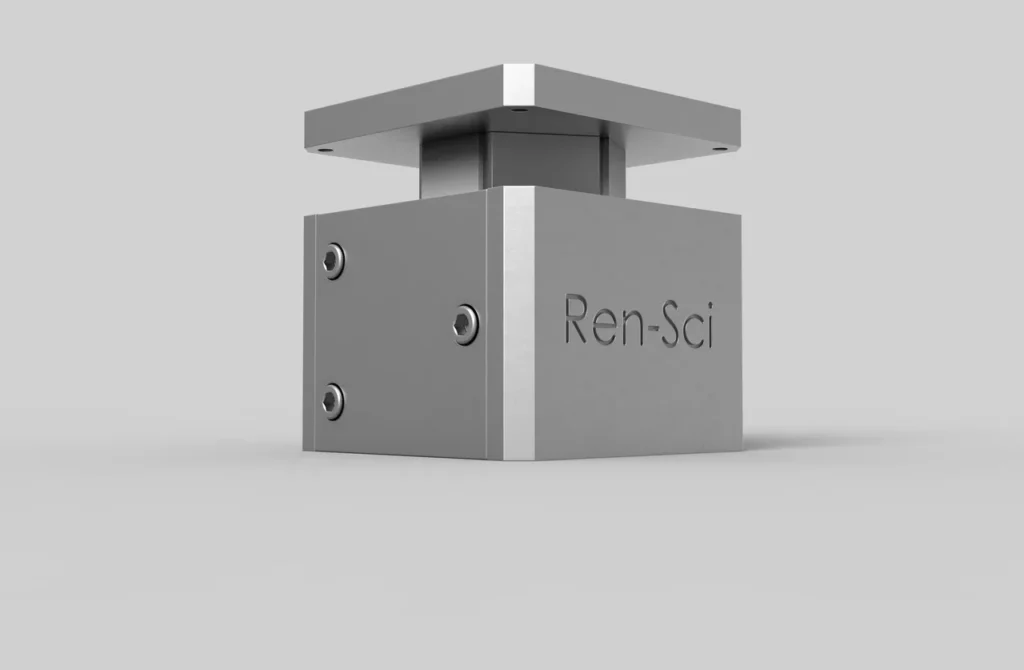

NP-340-X

- Footprint: 34mm x 34mm x 12mm

- Range: 15 mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

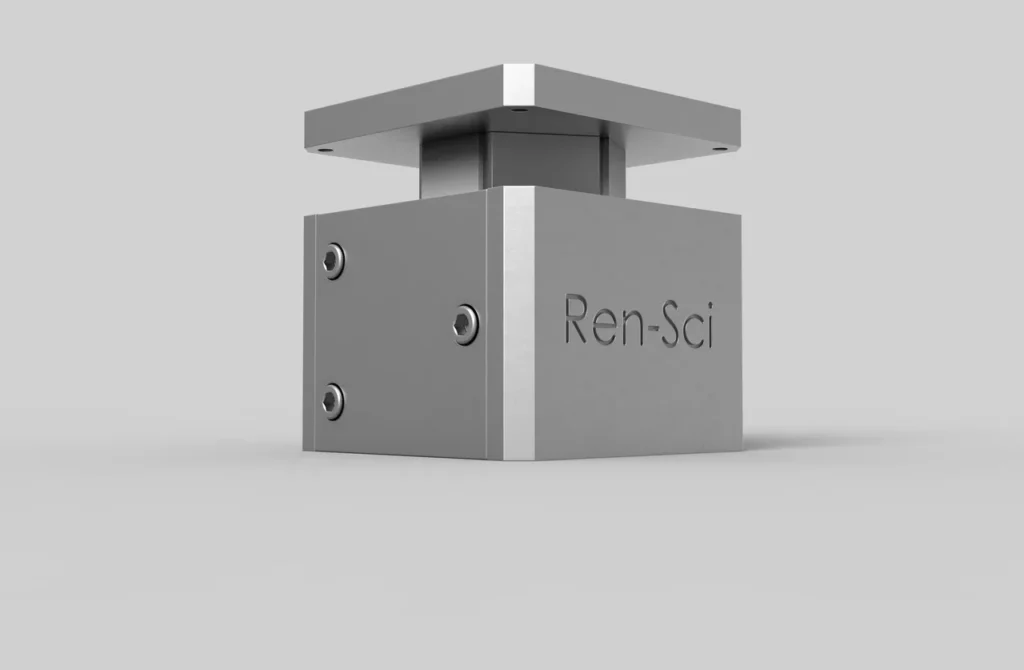

NP-240-Z

- Footprint: 24mm x 24mm x 20mm

- Range:5 mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

NP- 140-Z

- Footprint:14.5mm x 14.5mm x 20mm

- Range: 5 mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

NP-340-Z

- Footprint: 34mm x 34mm x 20mm

- Range: 15 mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

NP-450-Z

- Footprint: 45mm x 45mm x 20mm

- Range: 20 mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

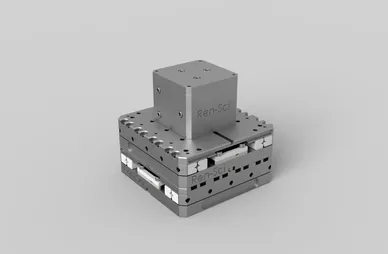

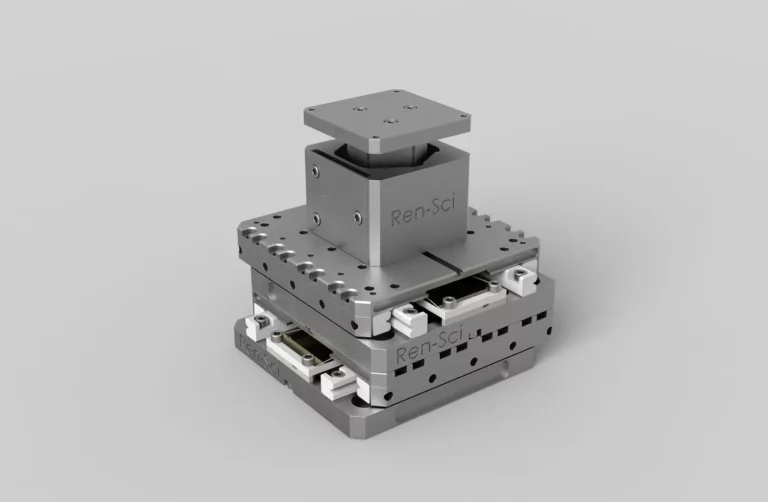

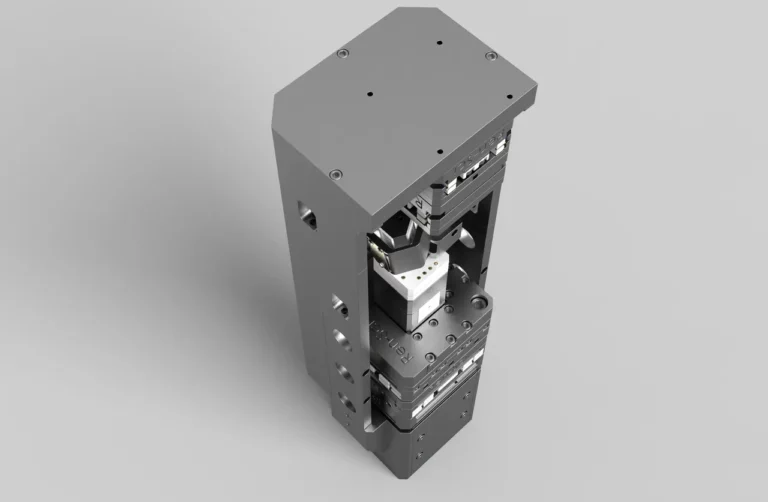

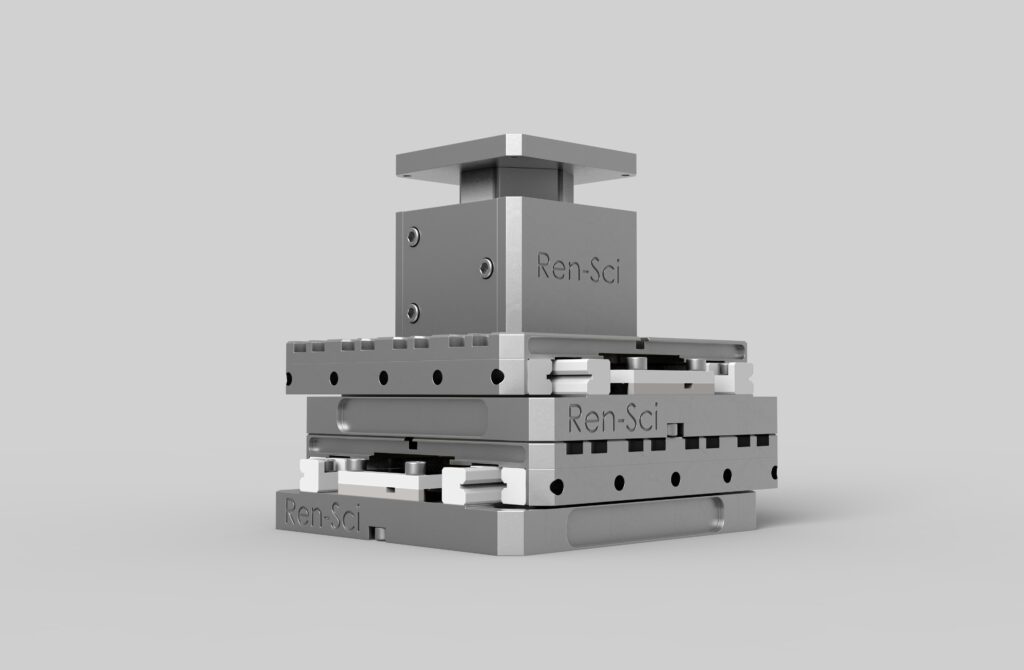

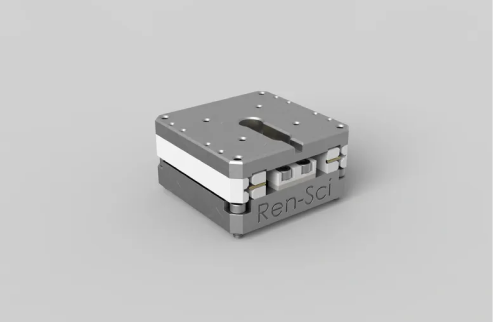

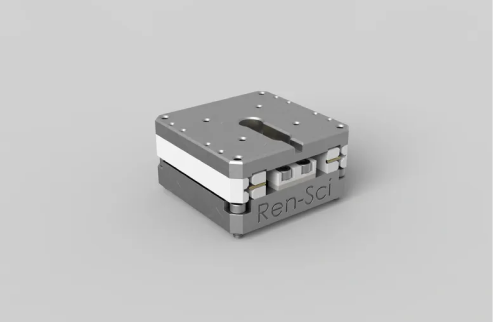

NP-240-XYZ

- Footprint: 24mm x 24mm x 44mm

- Range: 5mm x 5mm x 5mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

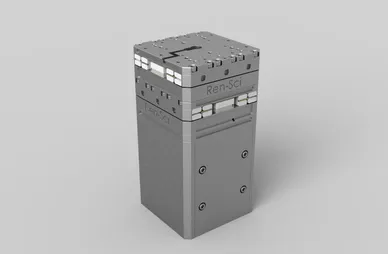

NP- 140- XYZ

- Footprint: 14.5mm x 14.5mm x 36mm

- Range: 3mm x 3mm x 3mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

- Capacitance 4K : X:1.8nF Z:3.8nF

- Drive Frequency (Hz) : 10 to 4000

NP-340-XYZ

- Footprint: 34mm x 34mm x 66mm

- Range: 15mm x15mm x 10mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

NP-340-XYZ-LR

- Footprint: 24mm x 24mm x 44mm

- Range: 5mm x 5mm x 5mm

- Encoding: Capacitance

- Multidirectional Repeatability: 8 to 150nm

- Sensor resolution 2 to 20nm

- Closed loop mode minimum incremental motion : 10 nm <

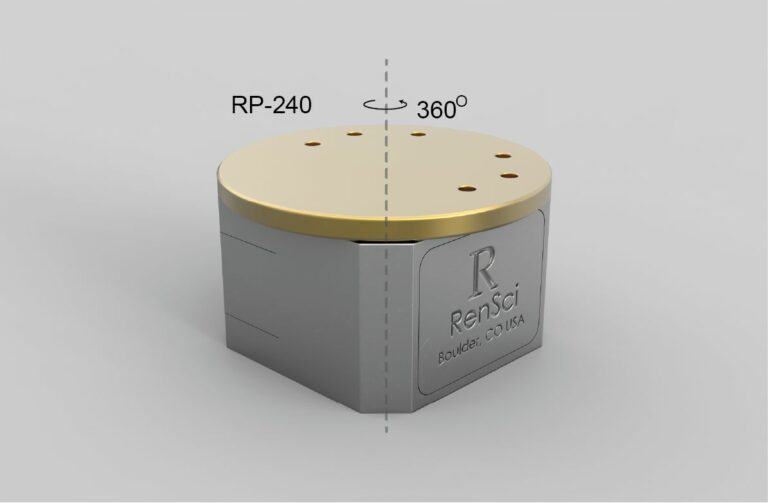

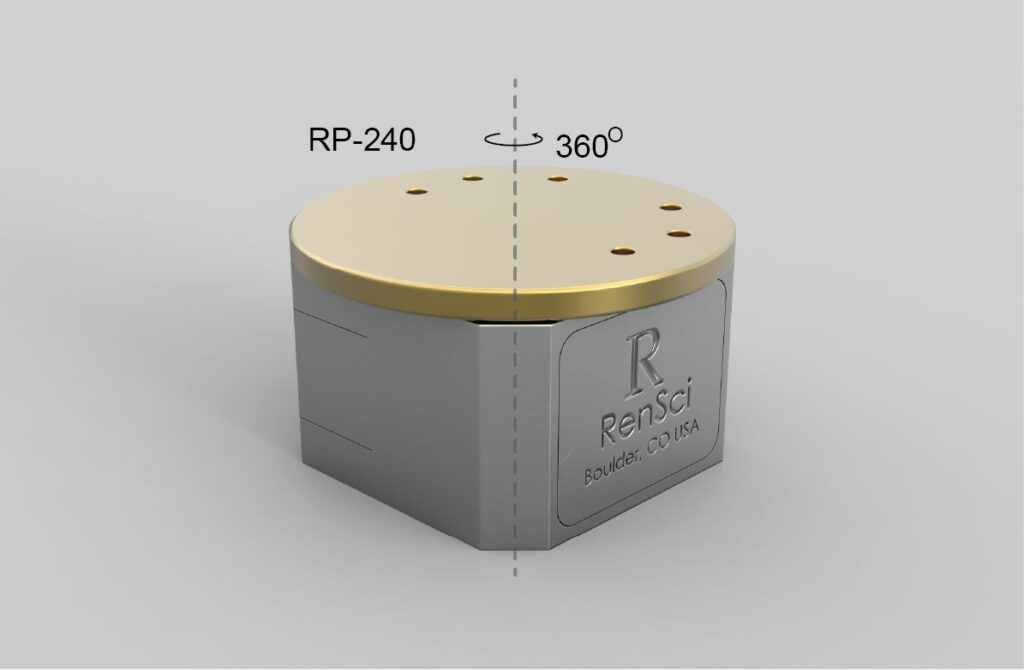

RP-240

- Footprint: 24mm x 24mm x 20mm

- Range: 360°

- Encoding: Capacitance

- Blocking force higher than industry standard

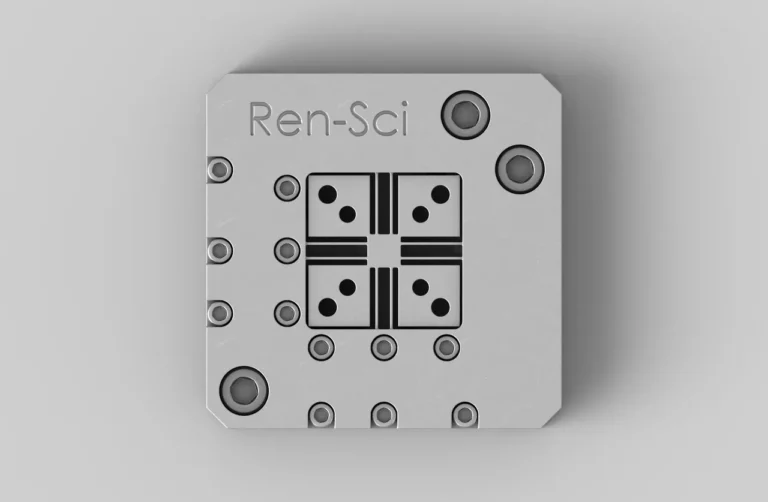

Dual Z Flexure Scanner

- Integrated Sample Holder

- Footprint: 14.5 mm x 14.5 mm x 24 mm

- Fast Scan Range: 250 nm @4K

- Large Scan Range: 12 um @4K

- Sample holder has 12 DC electrical contacts

- Independent variable temperature control of the sample (4K to 350K); sample island has onboard Cernox + heater

OTHER

OPTIONS

Need fiber connectors down in your large magnet? Fiber feedthrough shown with titanium FC/APC connector. 100% non-magnetic

Titanium lens tubes and rings (SM1) available. Stackable with varying heights. Build your own lens assembly for cryo without worrying about glass fracturing

fiber connectors that are non-magnetic, UHV, and cryogenic compatible. Only 3 materials: Ti (body), BeCu (spring), and ceramic zirconia (ferrule). No epoxies, these are all press-fitted together

How and Why

Game Changer on these applications

1

Scanning Probe Microscopy (thermal transport++)

Ultra Low Thermal dissipation.

Approach motion fast and accurate.

High stiffness and vibration insulation.

Unrivalled closed loop resolution

UHV and non-magnetic components.

User Replaceable actuators for intensive use.

2

NV Center

Unrivalled repeatability, navigate easily between the NV centers in your sample.

Large stroke range (>20mm), for large sample.

3

Nano-objects study

Nanometric minimum incremental motion.

Nanometric repeatability.

4

Quantum Photonics

Suitable for most challenging beam alignments.

Ultra Low Thermal dissipation.

Ultra Low noise.

Nanoscale accuracy.

5

Experiments below 300K

Ren-Sci positioners are simply indispensable for these experimental conditions

We rarely have the opportunity to distribute products that bring real new value to researchers and easily solve one of their persistent challenges.

Research applications have evolved towards ever-smaller objects, in ever-lower-temperature environments, while positioning tools have lagged behind.

Ryan has applied all his expertise to bridging this gap, and we are delighted that he has chosen us to spread the word locally.

Discovering and promoting manufacturers like Renaissance Scientific is at the core of what we want to do with Qnity.