Cryogenics

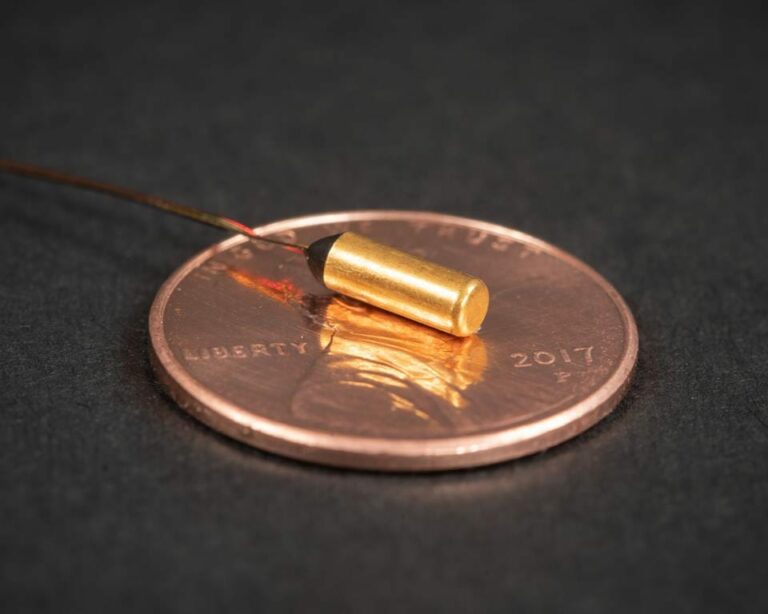

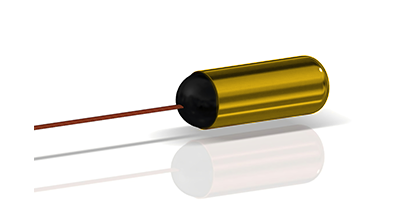

Series 56 Cryogenic Temperature Probes

Supplier :

- Robust Design for extreme environments

- High Precision

- Certified for immersion

Engineered for precise temperature measurements in extreme and hazardous environments, such as aerospace and cryogenic fuel systems.

Scientific Instruments offers a variety of temperature probes that allow mounting in hazardous environments. These units are constructed of stainless steel, hermetically sealed, and the sensing element is mounted in a thermal epoxy at the tip. The probes are designed for direct immersion or thermowell applications.

ABOUT

SYSTEM FEATURES

Highly Durable in Harsh Environments

Constructed with 316 stainless steel, these probes are corrosion-resistant and can withstand mechanical stress and chemical exposure—ideal for aerospace, cryogenic tanks, and industrial applications.

Hermetically Sealed

The hermetic sealing ensures zero gas or liquid ingress, enhancing reliability in pressurized or submersed environments (like rocket fuel systems or cryogenic storage tanks).

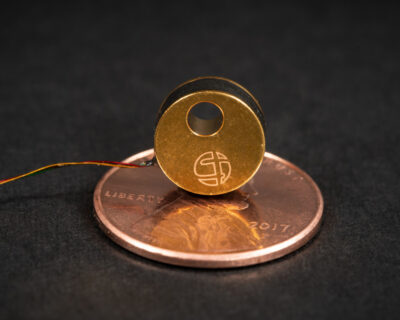

Custom Configurations Available

Available with various mounting styles, insertion lengths, and electrical connections, allowing integration into new or existing systems without redesign.

Low Self-Heating

The low excitation current (10 µA or 100 µA) minimizes self-heating, improving measurement accuracy at ultra-low temperatures.

Excellent Interchangeability

The SI-540 diode element has tight manufacturing tolerances and is calibrated to match standard temperature-voltage curves, allowing probe replacement without recalibration in many systems.

Proven Field Use

Used in critical aerospace and cryogenic fuel applications, including NASA and LNG systems, where precision and reliability are essential.

PRODUCT

SPECIFICATIONS

- Enclosure : All wetted areas are 316 SS.

- Insertion Length : Customer specified.

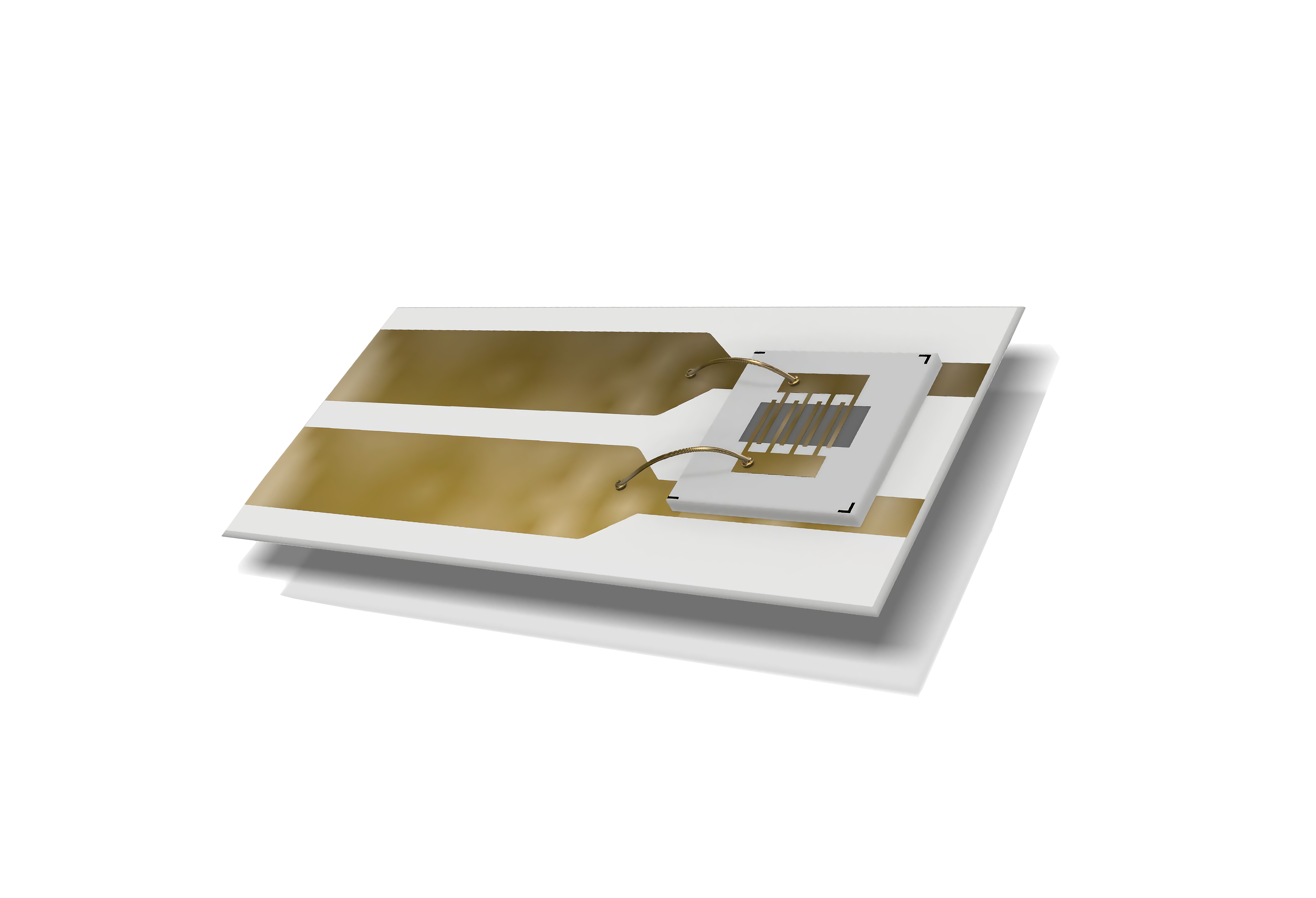

- Sensing Element : The sensing element is a silicon diode supported and contained in a closed housing

- Media Connection : Boss seal per MS33656E4

- Temperature Range : Each unit is capable of operating within an environmental temperature range of 1.5 K (-271.66°C) to 400 K (126.85°C)

- Operating Current : The operating current of the unit should be 10 microamperes (µA) ± 0.1µA for the 56D units and 100µA ± 1µA for 56DX (the sensor excitation is supplied by an external signal conditioner).

- Service Media : The unit will operate in the following gaseous or liquid media where compatible with the sheath-housing material and within the temperature range of the unit: Alcohol Neon (Ne) Ammonia (NH₃) Nitrogen (N₂) Helium (He) Nitrogen teroxide (N₂O₄) Hydrogen (H₂) Oxygen (O₂) Hydrazine (N₂H₄) Unsymmetrical dimethylhydrazine (UDMH) Monomenthylhygrazine (MMH) Water (H₂O)

- Repeatability : The unit is capable of repeating test parameter results under identical test conditions, within ± 0.1K (± 5 mVDC) at the boiling point of liquid helium and within ± 0.5K (1.2 mVDC) from 25 K to 400 K.

- Accuracy : The unit shall be accurate to within ± 0.25K (± 12.8 mVDC) from 1.5K to 25K and within ± 0.5K (1.2 mVDC) from 25K to 400K. (46DX and 46DX1, within ± 0.75K from 273K to 400K)

- Response Time : The unit shall respond within 63.2 percent of total temperature change, for a step change in temperature from 293.15 K ± 3K to 77.35 K ± 3K, within 15 seconds.

How and Why

Game Changer on these applications

1

Nuclear Fusion & High-Energy Physics

Installed in cryogenic cooling systems of tokamaks and particle accelerators.

2

Aerospace Engineering

Cryogenic fuel system monitoring in launch vehicles and re-entry

spacecraft.

Environmental testing in thermal vacuum chambers for flight hardware

3

Aerospace Fuel Systems

Essential in liquid hydrogen fuel tanks for rocket propulsion systems.

Deployed in feed lines, tank walls, and engine test beds to ensure safe, real-time thermometry during fueling and launch

4

Hydrogen-Powered Aviation

In emerging sectors like hydrogen-powered aircraft, the probes help monitor cryogenic fuel tanks and ensure safe combustion temperatures.

5

Liquid hydrogen infrastructures

Wide Temperature Range covering all phases of liquid hydrogen (boiling point at 20.27 K).

High Sensitivity allowing precise control and monitoring of hydrogen storage and transfer systems.

Low Excitation Current reduces heat dissipation, preventing unwanted temperature variations in liquid hydrogen systems

reviews

they liked it

For over 50 years Scientific Instruments has provided product and services that exemplify our expertise in cryogenic measurement. Although we support niche markets out of our facility in South Florida, we have a global reach. Being diversified has helped us to sustain our business over the years.

We are committed to providing the very best customer service and product support with our experienced staff and other fully trained, global distributors and representatives. Our team is committed to our goals and vision to be the worldwide leader in cryogenic measurement technology through continued innovation and advancements in technology

For more than 55 years, Scientific Instruments (SI) has been the quiet force behind everything from the Apollo lunar landings to today’s quantum computers.

If your program needs radiation-hard, field-immune sensors, flight- or H2 immerged-certified probes, or one sensor that spans milli-kelvin to 450 K, Scientific Instruments is the sharper tool in the box.

By joining forces with this illustrious company, Qnity has sealed a high-impact partnership for research and several strategic European industries (fusion, accelerators, aerospace, quantum, hydrogen mobility…).

Scientific Instruments supplies cryogenic instrumentation specially adapted to this type of need, with the very high level of traceability required.